- This topic is empty.

-

AuthorPosts

-

2025-12-16 at 11:32 am #6026

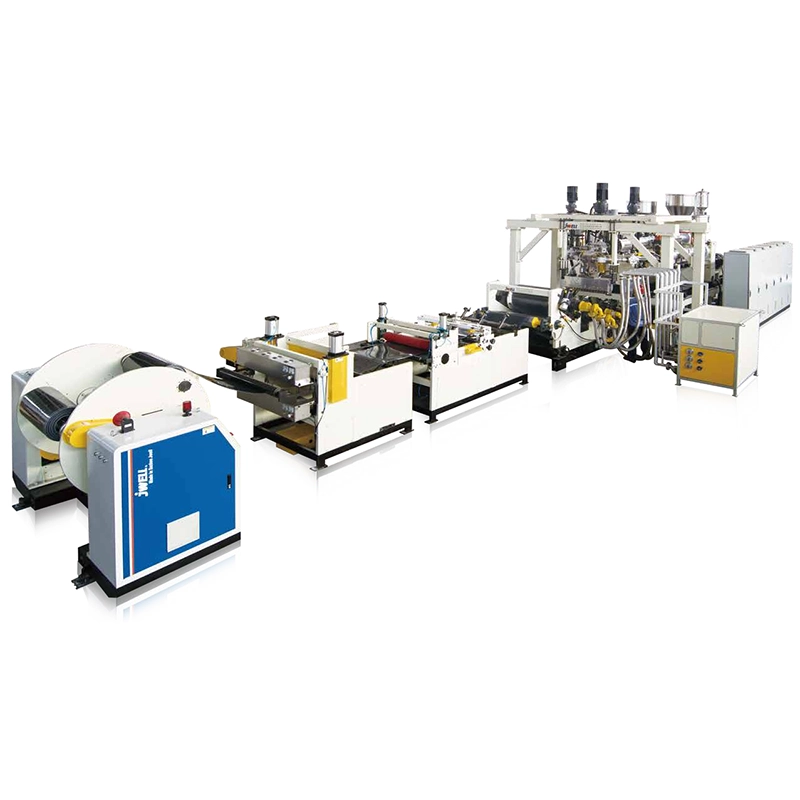

In the plastic processing industry, the sheet extrusion line plays a critical role in delivering stable, efficient, and scalable sheet manufacturing solutions. As demand grows across packaging, stationery, electronics, and automotive sectors, manufacturers increasingly rely on optimized extrusion systems capable of producing consistent-quality PP and PS sheets. In this blog post, Jwell Machinery, as high performance plastic sheet extrusion equipment exporter, will share the advantages of PP/PS Sheet Extrusion Line for plastic sheet production.

Core Design Concept of the PS Sheet Extrusion Line

A PS sheet extrusion line is designed as a standardized yet flexible production system. Its core objective is to ensure uniform melt plasticization, controlled sheet thickness, and continuous stable output. Compared with customized or overly complex sheet lines, this type of extrusion line emphasizes simplicity, reliability, and ease of operation, making it suitable for both medium-scale and high-capacity manufacturing plants.

The system usually integrates a high-efficiency extruder, precision T-die, polishing or calendering unit, cooling and shaping devices, haul-off unit, and cutting or winding system. Each module is engineered to work in coordination, reducing downtime and ensuring consistent product quality over long production cycles.

PP/PS Sheet Extrusion Line Structure and Working Principle

The PP/PS sheet extrusion line functions by melting raw polymer materials through controlled heating and screw rotation. Once the polymer reaches a uniform molten state, it is evenly distributed through the die to form a flat sheet. Downstream equipment then stabilizes the sheet’s surface finish, thickness accuracy, and mechanical properties.

For PS materials in particular, precise temperature control and smooth melt flow are essential. The extrusion system ensures that the PS sheet maintains clarity, rigidity, and dimensional stability, which are key performance indicators in downstream thermoforming and electronic packaging applications.

Advantages of Standardized PS Sheet Extrusion Line

One of the major strengths of a modern PS sheet extrusion line lies in its balance between performance and operational simplicity. These systems are engineered to provide:

-

High output capacity with consistent thickness control

-

Excellent plasticization for both PS and PP materials

-

User-friendly operation with reduced training requirements

-

Stable, low-vibration running suitable for long-term production

-

Lower maintenance demands compared with complex multi-purpose lines

Such advantages make the extrusion line particularly attractive for manufacturers seeking predictable output quality and efficient cost control.

Single-Layer and Multi-Layer PS Sheet Extrusion Solutions

A PS sheet extrusion line can be configured for single-layer or multi-layer production depending on product requirements. Single-layer systems are commonly used for transparent or opaque sheets with uniform material composition. Multi-layer configurations, on the other hand, allow co-extrusion of different materials or colors, enhancing functionality and visual appeal.

Co-extrusion technology enables the production of two-color sheets, double-side transparent sheets, or functional layered structures. These designs help manufacturers meet specialized market needs while optimizing material usage.

PS Thermoforming Sheet Production Capabilities

PS thermoforming sheets represent one of the most important product categories manufactured on a PS sheet extrusion line. These sheets are widely used in the packaging industry due to their excellent formability, rigidity, and surface finish.

During production, the extrusion line ensures that the sheet thickness remains uniform across the width, which is essential for consistent thermoforming results. High clarity and smooth surfaces also improve the appearance of finished packaging products, making them suitable for food containers, consumer goods packaging, and disposable trays.

PS Stationery Sheet Manufacturing Applications

In the stationery sector, PS sheets produced by a PS sheet extrusion line are valued for their dimensional stability and clean surface quality. Transparent sheets, dull polish sheets, and two-color sheets are commonly used for folders, covers, dividers, and document holders.

The extrusion process allows precise control over surface texture, enabling both fine and coarse matte finishes. This versatility supports diverse stationery designs while maintaining efficient large-scale production.

PP Foaming Sheet Production on Extrusion Lines

Although primarily associated with PS processing, many systems are designed as PP/PS extrusion solutions. PP foaming sheets produced on these lines serve a wide range of industrial purposes. The extrusion process introduces controlled foaming, resulting in lightweight sheets with sufficient rigidity.

PP foaming sheets are commonly used in stationery folders, packaging separation plates, and protective inserts. Beyond office and packaging uses, these sheets also find applications in automotive interior components such as visors, acoustic panels, luggage racks, and decorative covers.

Automotive and Industrial Uses of PP Foaming Sheets

The ability of a PS sheet extrusion line system to support PP foaming sheet production expands its industrial relevance. In automotive interiors, lightweight PP foaming sheets contribute to noise reduction, weight control, and improved energy efficiency.

Their ease of cutting, shaping, and surface treatment makes them suitable for interior decoration parts, storage boxes, and protective panels. The extrusion line ensures consistent foam structure, which directly impacts product durability and appearance.

PS Electricity Conductive Sheet Production Requirements

A specialized application of the PS sheet extrusion line is the production of electricity conductive PS sheets. These sheets are designed to meet stringent requirements for static control and dust-free environments.

Conductive PS sheets are mainly used for packaging semi-conductive electronic components and computer products. The extrusion process must ensure uniform dispersion of conductive additives to prevent static electricity buildup and radio frequency interference. Precision extrusion technology plays a decisive role in achieving these performance standards.

Quality Control in PS Sheet Extrusion Line Operation

Maintaining consistent quality is a key objective of any PS sheet extrusion line. Quality control begins with raw material selection and extends through every stage of the extrusion process. Parameters such as melt temperature, screw speed, die pressure, and cooling rate must be closely monitored.

Advanced control systems help operators maintain stable production conditions, reducing material waste and ensuring repeatable product performance. This systematic approach is essential for industries where dimensional accuracy and surface quality are non-negotiable.

Operational Efficiency and Ease of Use

Another defining characteristic of a modern PS sheet extrusion line is its operational efficiency. Intuitive control interfaces, modular equipment layout, and automated adjustment functions simplify daily operation. This reduces dependence on highly specialized labor and minimizes the risk of operational errors.

Stable running performance also means fewer unexpected shutdowns, which directly improves overall equipment utilization and production planning reliability.

Scalability and Customization Potential

While standardized in design, a PS sheet extrusion line offers significant scalability. Manufacturers can expand capacity by upgrading extruders, adding co-extrusion units, or integrating downstream automation systems.

Customization options allow the line to adapt to changing market demands, whether that involves new sheet dimensions, material formulations, or functional properties. This flexibility ensures long-term investment value for production enterprises.

Environmental and Material Efficiency Considerations

Modern PS extrusion systems increasingly focus on material efficiency and environmental performance. Optimized screw designs improve melt efficiency, reducing energy consumption per unit output. Precise thickness control minimizes raw material waste.

In addition, the extrusion line can process recycled PS materials under controlled conditions, supporting sustainable manufacturing practices without compromising product quality.

Future Trends in PS Sheet Extrusion Line Development

As downstream industries continue to evolve, the PS sheet extrusion line is expected to integrate smarter control technologies and higher levels of automation. Digital monitoring, predictive maintenance, and enhanced energy management will further improve productivity and cost efficiency.

At the same time, demand for functional sheets such as conductive, foamed, and multi-layer products will drive continued innovation in extrusion line configuration and process optimization.

Conclusion on PS Sheet Extrusion Line Value

The PS sheet extrusion line remains a cornerstone of plastic sheet manufacturing, supporting a wide range of applications from packaging and stationery to electronics and automotive interiors. Its combination of high capacity, stable operation, and versatile production capability makes it a practical and future-ready solution for manufacturers seeking consistent quality and operational efficiency.

By leveraging well-engineered PP/PS single-layer and multi-layer extrusion systems, producers can respond effectively to market demands while maintaining long-term production stability and competitiveness.

http://www.jwellplas.com

Jwell -

-

AuthorPosts

- You must be logged in to reply to this topic.