- This topic is empty.

-

AuthorPosts

-

2025-11-07 at 6:07 pm #5515

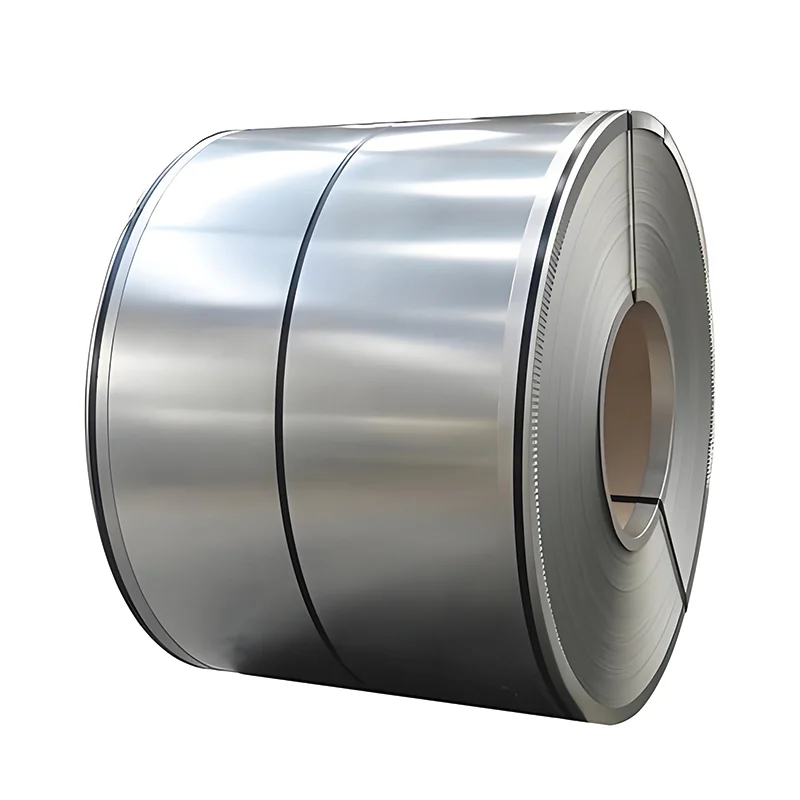

A36 carbon steel is one of the most widely used structural steel grades in industrial applications due to its versatility, durability, and cost-effectiveness. Selecting the right A36 carbon steel coil is essential to ensure project efficiency, structural integrity, and compliance with industry standards. Whether you are working in construction, manufacturing, or heavy industry, understanding the key specifications and considerations will help you make an informed choice.

Fuchuan Metal Co., Ltd., a leading stainless steel exporter and metal solutions provider, specializes in stainless steel coils, plates, tubes, high-temperature alloys, Hastelloy, nickel-based alloys, aluminum, and copper products. Their materials are widely used in industries such as chemical, petroleum, synthetic fiber, paper, natural gas, nuclear power, boiler heat exchangers, shipbuilding, food machinery, environmental engineering, construction, and aerospace. Leveraging their expertise ensures you select the best A36 carbon steel coil for your specific project requirements.

1. Understanding A36 Carbon Steel Coil

A36 carbon steel is a mild steel grade known for its:

-

Good weldability and machinability, making it suitable for a variety of fabrication processes.

-

High strength-to-weight ratio, providing structural reliability without excessive material costs.

-

Versatility, allowing it to be used in construction, machinery, pipelines, and manufacturing components.

In coil form, A36 steel is rolled into long, continuous sheets, which simplifies handling, storage, and transportation, making it ideal for large-scale industrial applications.

2. Key Factors When Choosing A36 Carbon Steel Coil

When selecting an A36 carbon steel coil, consider the following factors:

a. Thickness and Width

-

The coil thickness should match your project’s load-bearing and fabrication requirements.

-

Width affects handling, cutting efficiency, and compatibility with machinery.

b. Coil Weight

-

Heavier coils may require specialized handling equipment.

-

Ensure your production line can accommodate the coil weight for safe and efficient operations.

c. Surface Finish

-

Cold-rolled coils provide smoother finishes for precise machining and aesthetic requirements.

-

Hot-rolled coils are more suitable for heavy-duty structural applications.

d. Certification and Standards

-

Verify that the supplier meets international standards such as ASTM A36, ensuring the steel’s mechanical properties and chemical composition are consistent.

e. Supplier Expertise

-

Partnering with a reputable supplier like Fuchuan Metal Co., Ltd. ensures you receive high-quality coils, technical support, and customization options based on project needs.

3. Applications of A36 Carbon Steel Coil

A36 carbon steel coils are used in a variety of industrial sectors:

-

Construction: Structural beams, columns, and steel frameworks.

-

Shipbuilding: Hulls, decks, and other structural components.

-

Manufacturing: Machinery parts, storage tanks, and heavy equipment.

-

Energy and Utilities: Boiler systems, heat exchangers, pipelines, and pressure vessels.

-

Aerospace and Automotive: Non-critical structural components that require weldability and strength.

By selecting the appropriate coil thickness, finish, and weight, you can ensure project efficiency and long-term performance.

4. Benefits of Sourcing from Fuchuan Metal Co., Ltd.

Choosing a reliable supplier is crucial for quality and consistency. Fuchuan Metal Co., Ltd. offers:

-

Wide Product Range: Stainless steel coils, plates, tubes, nickel alloys, copper, and aluminum products.

-

Industry Expertise: Materials suitable for chemical, petroleum, paper, shipbuilding, nuclear, and aerospace industries.

-

Quality Assurance: Compliance with international standards such as ASTM and ISO.

-

Customization: Coil sizes, thicknesses, and finishes tailored to your specific project requirements.

-

Global Supply Chain: Efficient logistics for timely delivery and reliable service.

Their extensive experience ensures that you receive high-quality A36 carbon steel coils optimized for your industrial projects.

5. Tips for Handling and Storage

Proper handling and storage of steel coils are essential to prevent damage and corrosion:

-

Store coils in covered, dry areas to avoid moisture exposure.

-

Use lifting equipment appropriate for the coil weight to prevent deformation.

-

Maintain inventory rotation, using older coils first to ensure material freshness.

-

Protect edges and surfaces with coatings or packaging materials to prevent scratches and rust.

Fuchuan Metal can provide guidance on best practices for storage and handling, ensuring your coils maintain their integrity until use.

Conclusion

Selecting the right A36 carbon steel coil involves understanding thickness, width, surface finish, certifications, and supplier expertise. These factors directly impact the structural performance, fabrication efficiency, and long-term durability of your industrial projects.

Fuchuan Metal Co., Ltd. provides high-quality A36 carbon steel coils backed by extensive industry experience, global supply capabilities, and customizable solutions. By partnering with Fuchuan, you ensure your projects receive reliable materials that meet mechanical, chemical, and structural requirements, whether in construction, shipbuilding, energy, or manufacturing applications.

http://www.fuchuansteel.com

Fuchuan Metal Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.